PREMISE

Thousands of operators work on assembly lines on the manufacturing floor at various locations of a large manufacturing company. The company had no definitive measure to assess efficiency and quality at various levels—organizational, team and individual—and to identify “masters” or trainers vs learners or trainees. Assessment was made even more difficult by a high attrition rate. The challenge was to do all this even though operator-specific data was not available!

SOLUTION

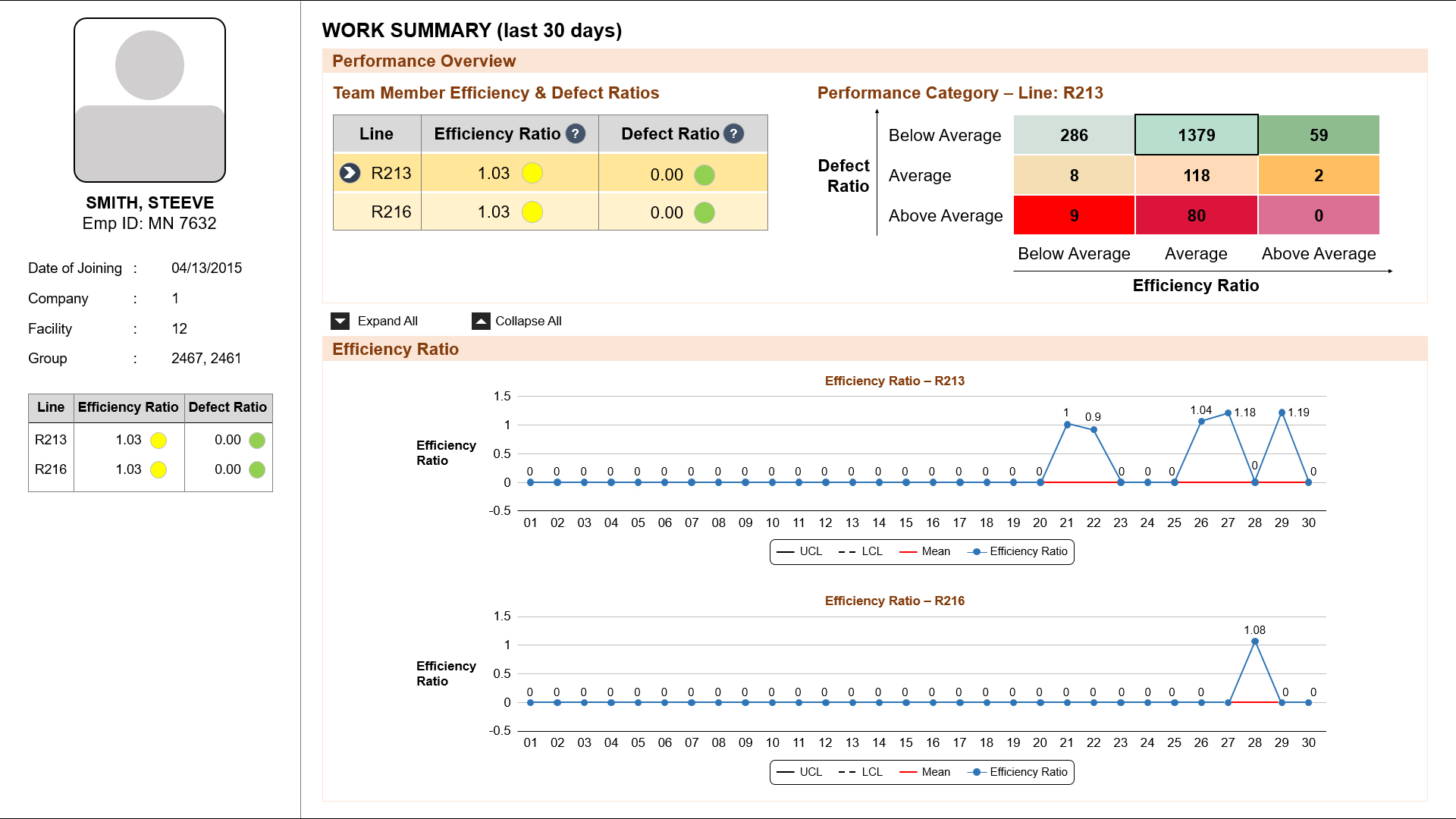

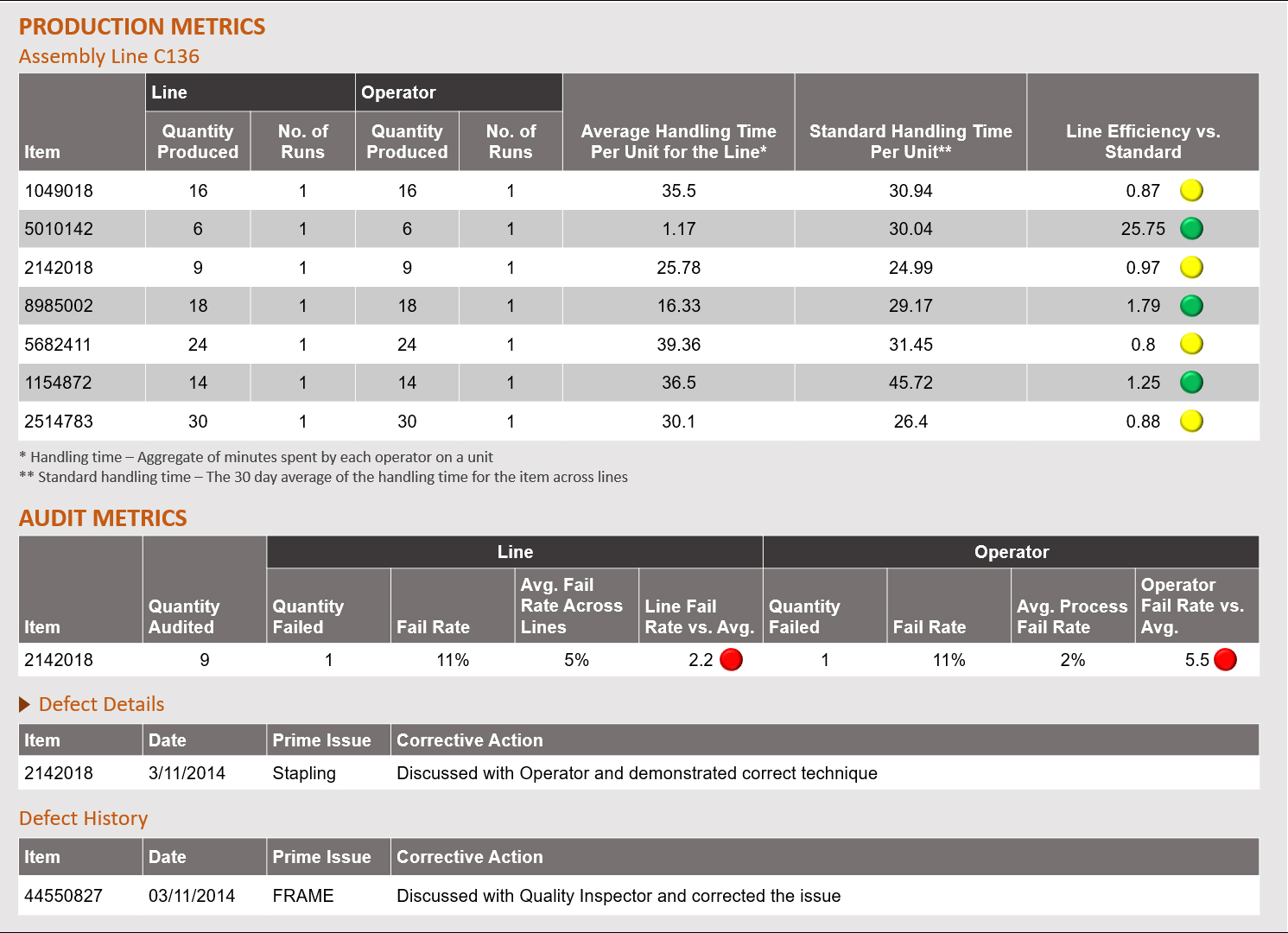

Customer Analytics created a “scorecard” to assess efficiency and quality at operator, team, supervisor and above levels. This was based on production run data from which measures relating to efficiency, such as handling time, were created. Defect-related data were used to derive quality metrics.